double deep warehouse racking

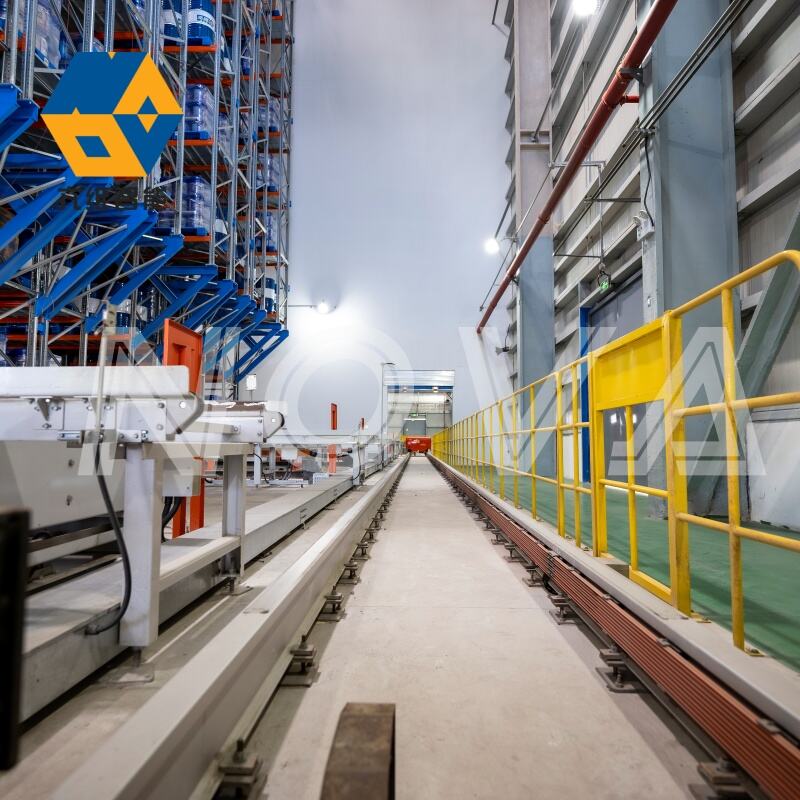

Double deep warehouse racking represents a sophisticated storage solution that maximizes warehouse space utilization by allowing pallets to be stored two deep on each side of an aisle. This innovative system effectively doubles the storage density compared to traditional single-deep racking, making it an ideal choice for facilities dealing with large quantities of similar products. The system consists of sturdy steel frames and beams designed to support multiple pallet loads, arranged in a configuration that enables forklifts to access the second pallet position. Modern double deep racking systems incorporate advanced safety features, including load indicators, protective guards, and reinforced base plates. The technology employs specialized reach trucks equipped with telescopic forks capable of extending to access the rear pallet positions. This racking system particularly excels in cold storage environments, bulk storage operations, and facilities with high-volume, slow-moving inventory. The design typically includes adjustable beam levels, allowing for flexible storage configurations to accommodate various pallet sizes and weights. While requiring specific handling equipment and careful planning, double deep racking delivers substantial space efficiency benefits, making it a valuable investment for warehouses seeking to optimize their storage capacity.