- Преглед

- Свързани продукти

- Градежни материали и строителство: Конзолните рафтове се отличават при съхранение на дървен материал, стоманени греди, тръби, ПВЦ тръби и листови материали (фанера, гипсокартон). Отвореният фасаден дизайн позволява на вилов погрузач лесно да достига до артикулите отстрани, улеснявайки товаренето и разтоварването на дълги обекти, често срещани в този сектор.

- Металообработка и производство: Те са идеални за съхранение на метални суровини като пръти, пръти, тръби, профили и плочи. Възможността да издържат тежки натоварвания и осигуряват свободен достъп подпомага ефективния поток на материали в производствените среди.

- Автомобилна и аерокосмическа: Тези индустрии използват конзолни рафтове за съхранение на дълги компоненти като изпускателни системи, оси, части от шасита, крилни греди и корпусни секции. Масивната конструкция издържа теглото на тези често тежки предмети.

- Мебели и фиксирани вътрешни врати: Производителите и дистрибуторите съхраняват ефективно рамки за легла, маслени плочи, работни плота, врати и прозоречни рамки в конзолни системи.

- Хартия, печат и текстил: Големите ролки с хартия, плат, винил или килим са идеални за складиране в конзолни рафтове. Конзолите могат да бъдат настроени според диаметъра на ролката, за да се предотврати деформация.

- Пластмасова индустрия: Складирането на пластмасови листове, пръти, тръби и екструзии е често срещано приложение, от което се печели от лесния достъп и поддържане, осигурено от конзолните ръце.

- Ландшафтна архитектура и земеделие: Материали за ограждане, тръби за напояване, рамки за парникове и дълги дръжки на инструменти намират ефективно място в конзолни рафтове.

- Оптимизация на пространството: Конзолните системи използват отлично вертикалното пространство и могат да бъдат конфигурирани в дълги редици с високи тавани, като максимизират плътността на складиране в границите на склада. Дълбоките конфигурации позволяват значителна дълбочина на складиране, без да се компрометира достъпността.

- Подобрена достъпност и обработка: Отвореният дизайн позволява на погрузчици или специализирана техника (като странични товарачи) директен достъп отстрани на рафта. Това премахва необходимостта от маневриране в тесни проходи и значително ускорява времето за обработване на товарите в сравнение с други типове рафтове.

- Гъвкавост и адаптивност: Височината и положението на конзолите обикновено са регулируеми. Това позволява лесна преустройване за съхранение на предмети с различна дължина, диаметър или тегло, когато се променят нуждите от инвентаризация. Често могат да бъдат добавени нови конзоли за увеличаване на капацитета.

- Подобряване на безопасността: Правилно проектираните и монтирани конзолни рафтове осигуряват стабилна подкрепа за дълги или тежки предмети, намалявайки риска от повреди на продуктите или злополуки, причинени от нестабилни товари. Те са проектирани да отговарят на строги стандарти за безопасност (напр. OSHA, RMI, EN).

-

Доброкачественост и висок товароносимост: Изработени от здрава стомана, конзолните рафтове са проектирани да издържат значителни статични и динамични натоварвания, което ги прави подходящи за тежки индустриални приложения.

Приложения на конзолните стелажни системи в модерното складиране

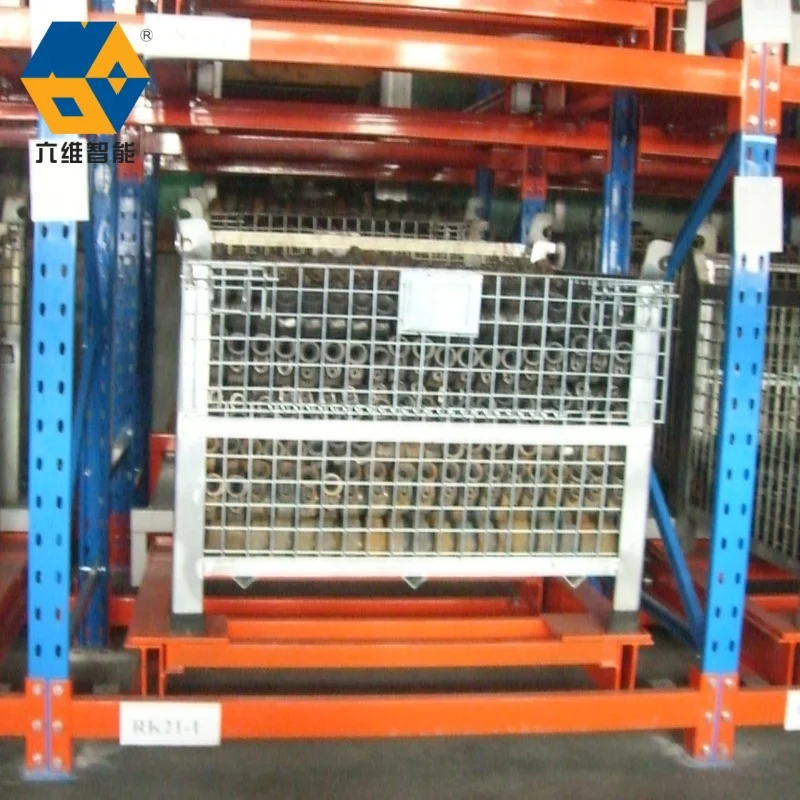

Конзолните стелажни системи представляват специализирано решение за съхранение, предназначено за ефективно управление на дълги, обемисти или неправилно оформени предмети. За разлика от обикновените палетни стелажи, конзолните системи имат рамена, разположени от вертикални колони, които създават открити отделения за съхранение, идеални за дълги материали. Този уникален дизайн предлага безпрецедентна гъвкавост и достъпност, което ги прави незаменими в различни индустрии.

Основни области на приложение:

Основни предимства, задвижващи внедряването:

Заключение:

Системите за стелажи с конзоли са високоспециализирано и ефективно решение за индустрии, които работят с дълги, обемисти или неправилно оформени запаси. Като предлагат превъзходно използване на пространството, изключителна достъпност, вродена гъвкавост и висока носимоспособност, те опростяват складовите операции, подобряват безопасното и допринасят значително за общата ефективност на веригата за доставки. Уникалният им дизайн решава специфични проблеми при съхранение, които обикновените палетни стелажи не могат ефективно да преодолеят, което затвърждава тяхната съществена роля в съвременното индустриално складиране и логистика.