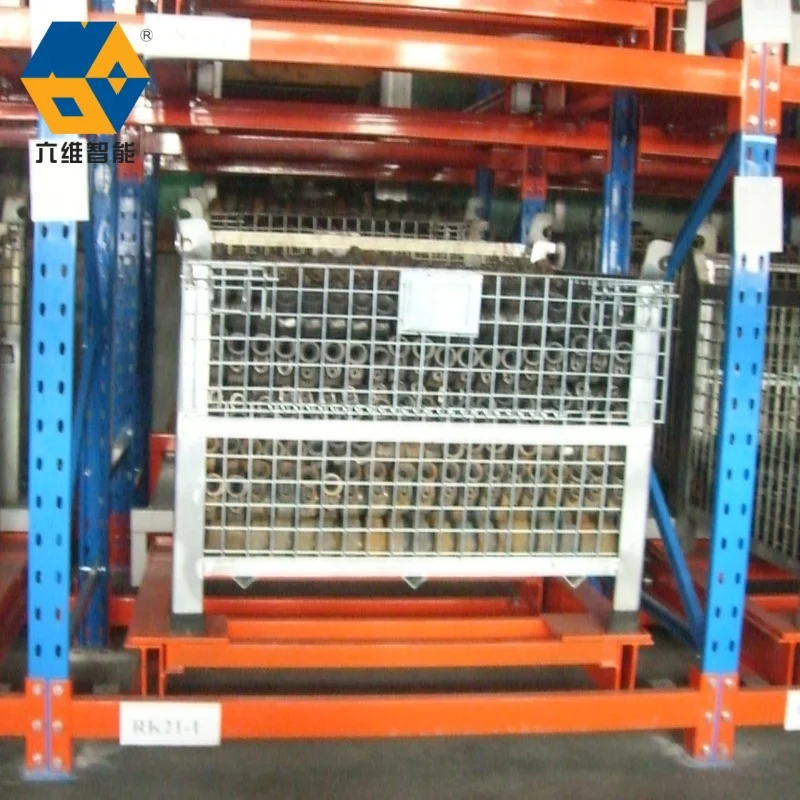

China Großhandel Industrielager Doppelseitige Langarm Rohr-Ablage Schwerlast-Metall-Freiträger-Holzregale System

- Überblick

- Verwandte Produkte

Anwendungsrichtungen von Cantilever-Regalen

Cantilever-Regale, gekennzeichnet durch waagerechte Ausleger, die sich von vertikalen Pfosten erstrecken, werden häufig in Branchen eingesetzt, in denen eine effiziente Lagerung von langen, sperrigen oder unregelmäßig geformten Gegenständen erforderlich ist. Ihre Vielseitigkeit, Langlebigkeit und platzsparende Konstruktion machen sie in verschiedenen Bereichen unverzichtbar. Nachfolgend sind die wichtigsten Einsatzbereiche für Cantilever-Regale aufgeführt:

1. Bau- und Baustoffe

Stützenlager eignen sich hervorragend zum Lagern langer Baustoffe wie Stahlstäbe, Rohre, Holz und PVC-Rohre. Durch die offene Bauweise ist eine einfache Beladung und Entladung mit Gabelstaplern oder Kränen möglich, wodurch der Arbeitsablauf in Baustofflagern verbessert wird. Die verstellbaren Ausleger passen sich unterschiedlichen Längen und Gewichten an, reduzieren Materialschäden und erhöhen die Sicherheit.

2. Fertigung und Metallbearbeitung

Fabriken, die Metallbleche, Stangen oder stranggepresste Profile verarbeiten, profitieren von der hohen Tragfähigkeit von Stützenlagern (häufig 1.000–5.000 lbs pro Ausleger). Die Regale ermöglichen eine systematische Ordnung der Rohstoffe, verringern Unordnung und optimieren den Platzbedarf. Geschmiedete oder geschweißte Stahlrahmen widerstehen rauen industriellen Umgebungen und gewährleisten eine lange Lebensdauer.

3. Einzelhandel und Großhandelsverteilung

Große Einzelhandelslager nutzen Stützenlager zur Aufbewahrung von Möbeln, Teppichen oder Sanitäranlagen. Die Konstruktion ermöglicht direkten Zugriff auf die Artikel und beschleunigt die Kommissionierung. Händler können die Regalhöhen an hoch aufragende Gebäude anpassen, um den vertikalen Stauraum zu maximieren, ohne die Gänge zu blockieren.

4. Automobil- und Luftfahrtindustrie

Diese Regale lagern überdimensionale Teile wie Abgaskrümmer, Aluminiumflügel oder Fahrwerkskomponenten. Korrosionsbeständige Beschichtungen (z. B. Pulverbeschichtung) schützen die Regale in feuchten oder chemisch belasteten Bereichen. Einige Varianten verfügen über modulare Erweiterungen, um sich ändernde Lagerbedürfnisse zu berücksichtigen.

5. Landwirtschaftliche und forstwirtschaftliche Anwendungen

Landwirtschaftsbetriebe und Holzhändler nutzen Kragarmregale zur Aufbewahrung von Bewässerungsrohren, Zäunen oder Baumstämmen. Verzinkte Ausführungen widerstehen Rost in Außenbereichen, während kiesgefüllte Fundamente Stabilität auf unebenem Gelände bieten.

6. Spezielle Anpassungen

Fortgeschrittene Kragarm-Systeme lassen sich in automatisierte Lagertechnik (AS/RS) oder RFID-Tracking für hochmoderne Lager integrieren. Verstellbare Auslegerwinkel (z. B. 15°–45°) verhindern das Herunterrollen von Gegenständen wie Zylindern.

Fazit

Fahrbare Regale bieten maßgeschneiderte Lösungen für Branchen, die auf Raumeffizienz, Lastanpassungsfähigkeit und Langlebigkeit Wert legen. Durch die Auswahl geeigneter Materialien (Stahl, Aluminium) und Konfigurationen können Unternehmen ihre Abläufe optimieren, Handlingskosten senken und die Arbeitssicherheit verbessern. Zukünftige Trends könnten regale mit IoT-Funktionalität für das Echtzeit-Inventarmanagement umfassen, wodurch ihre Rolle in der intelligenten Logistik weiter gestärkt wird.