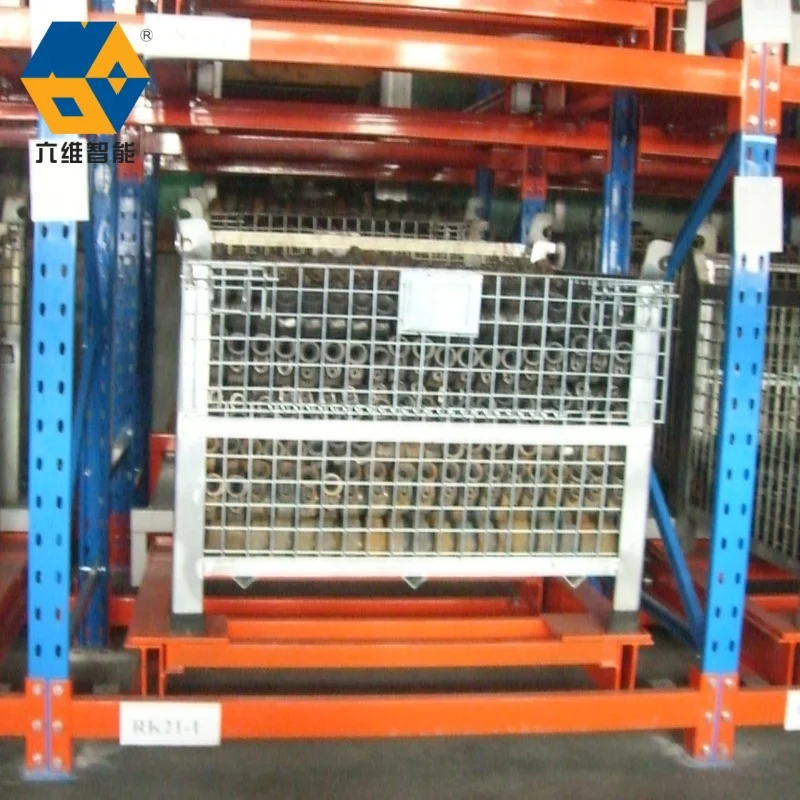

Sistem Rak Kantilever Industri Tugas Berat Custom Pabrik untuk Gudang, Rak dan Shelving Penyimpanan Tahan Lama

- Gambaran Umum

- Produk Terkait

- Logam: Batang baja, tabung, pipa, lembaran, kumparan, dan profil struktural.

- Material bangunan: Kayu gelondongan (kayu), lembaran kayu lapis, papan gipsum (drywall), pipa PVC, saluran, dan batang tulangan (rebar).

- Plastik: Pipa plastik, ekstrusi, dan gulungan film atau kain.

- Perabotan: Komponen panjang, pintu, jendela, dan kasur.

-

Lainnya: Karpet, gulungan kertas, dan cetakan besar.

- Penyimpanan Dingin: Menyimpan makanan panjang (seperti ikan beku atau daging olahan) atau bahan kemasan.

-

Otomotif: Menyimpan komponen panjang, sistem pembuangan, atau panel bodi. * Dirgantara: Menyimpan bahan komposit, pipa, atau bagian memanjang lainnya. * Penyimpanan Bahan Berbahaya: Dengan protokol keselamatan yang sesuai dan kemungkinan pelapis khusus.

- Penyimpanan Tanpa Pallet: Penyimpanan langsung menghilangkan kebutuhan akan pallet, menghemat biaya dan ruang.

- Pemanfaatan ruang tinggi: Penyimpanan padat, terutama secara vertikal, memaksimalkan kapasitas kubik gudang.

- Akses Tak Terbatas: Pemuatan samping memungkinkan forklift atau derek menempatkan dan mengambil barang dengan cepat dan mudah.

- Fleksibilitas: Lengan dapat disesuaikan secara vertikal untuk mengakomodasi ketinggian dan panjang barang yang berbeda. Konfigurasi dapat berkisar dari rak satu sisi yang menempel dinding hingga lorong dua sisi.

- Daya Tahan: Dirancang untuk menangani beban berat yang terkonsentrasi pada lengan-lengan rak.

Arah Aplikasi Rak Kantilever: Fleksibilitas untuk Barang Panjang dan Besar

Rak kantilever adalah sistem penyimpanan khusus yang dirancang secara khusus untuk barang yang panjang, besar, berbentuk tidak beraturan, atau sulit ditangani dengan palet. Ciri utamanya adalah tidak adanya kolom depan. Sebagai gantinya, rak ini terdiri dari kolom vertikal (tegak) dengan lengan kantilever yang menjorok secara horizontal dari kolom tersebut. Struktur unik ini menciptakan bagian depan yang terbuka, memungkinkan pemuatan dan pembongkaran barang tanpa hambatan dari samping.

Desain ini menjadikan rak kantilever solusi optimal di beberapa area aplikasi utama:

1. Gudang & Logistik untuk Barang Longitudinal: Ini adalah aplikasi yang paling umum. Rak kantilever unggul dalam menyimpan barang seperti:

2. Manufaktur & Penyimpanan Bahan Mentah: Pabrik dan bengkel sangat bergantung pada rak kantilever untuk menyimpan bahan mentah yang menunggu diproses (seperti billet logam atau stok panjang) dan barang setengah jadi. Akses terbuka memudahkan pengambilan untuk tahap produksi berikutnya, mendukung alur kerja yang efisien (prinsip JIT).

3. Konstruksi & Suplai Bangunan: Penyedia bahan bangunan dan gudang kayu lapis menganggap rak kantilever sangat penting. Rak ini memberikan penyimpanan terorganisir dengan kepadatan tinggi untuk barang-barang panjang dan berat yang menjadi inti industri konstruksi. Forklift dapat dengan mudah mengakses material langsung dari lengan rak, mempercepat pemilihan pesanan dan pengiriman.

4. Pusat Distribusi Ritel: Untuk pengecer yang menjual barang panjang (misalnya toko DIY yang menyediakan kayu, pipa, atau alat berkebun), rak kantilever di pusat distribusi mereka memungkinkan penyimpanan massal yang efisien dan konsolidasi pesanan sebelum dikirim ke toko.

5.Lingkungan Khusus: Rak kantilever juga dapat disesuaikan untuk:

Keunggulan Utama yang Mendorong Aplikasi ini:

Secara intinya, rak kantilever adalah solusi utama di mana pun barang panjang, besar, atau yang tidak dipallet membutuhkan penyimpanan yang efisien, mudah diakses, dan berkepadatan tinggi. Kemampuannya yang mudah disesuaikan menjadikannya komponen penting dalam strategi penanganan material di berbagai industri.