- 개요

- 관련 제품

캔틸레버 랙의 적용 분야

캔틸레버 랙은 오픈 프론트 구조와 높은 하중 지지 용량 덕분에 다양한 산업 분야에서 널리 사용되는 다용도 저장 시스템입니다. 주요 적용 분야는 다음과 같습니다.

긴 길이 및 부피가 큰 물품 저장

파이프, 목재, 철근, 가구와 같이 길거나 비정형적인 물품 저장에 이상적입니다. 전면에 기둥이 없어 포크리프트나 크레인을 이용한 적재 및 하역이 용이합니다.

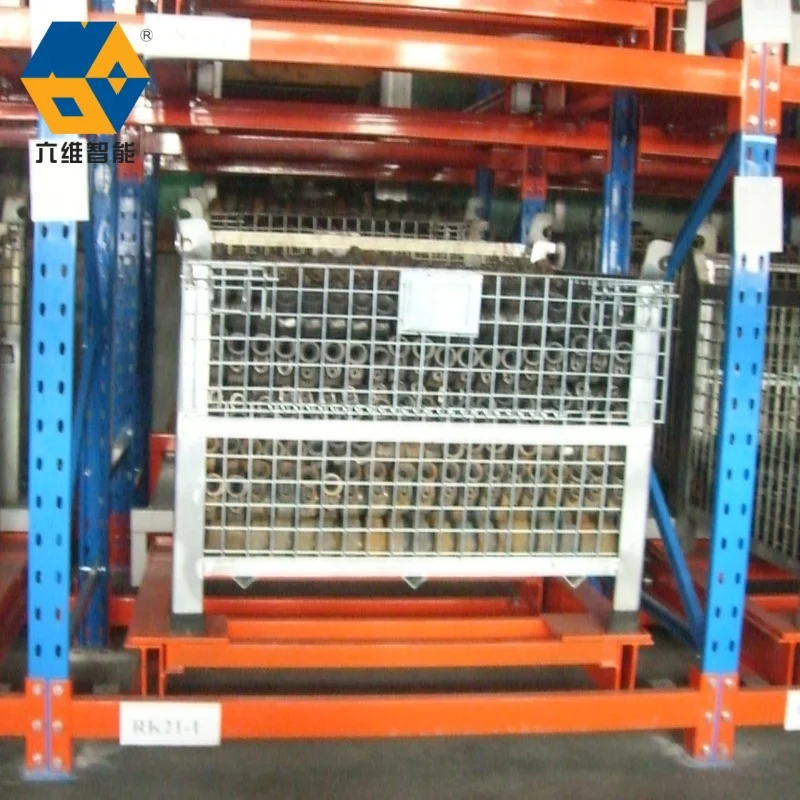

창고 및 물류

과도한 크기의 상품을 공간 효율적으로 저장하기 위해 창고에서 일반적으로 사용되며, 혼잡함을 줄이고 접근성을 향상시킵니다. 조절형 암은 다양한 크기의 물품에 맞게 맞춤 설정이 가능합니다.

제조 및 건설

공장 및 건설 현장에서 철근, PVC 튜브와 같은 원자재를 정리하고 작업 흐름의 효율성을 유지하기 위해 필수적입니다. 내구성이 뛰어나 중장비 환경에 적합합니다.

소매 및 도매

도매 판매점에서 카펫, 패널 또는 자동차 부품과 같은 제품의 대량 전시를 지원하여 시각적 매력을 높이고 재고 관리를 개선합니다.

냉장 보관

냉동 보관 시설에서 스테인리스 스틸 캔틸레버 랙은 부식에 강해 냉동 식품이나 의약품 저장을 위한 공간을 제공합니다.

자동차 및 항공우주

배기 파이프, 항공기 날개와 같은 긴 부품을 안전하게 보관할 수 있으며, 이동식 베이스 옵션을 통해 배치를 재구성할 수 있습니다.

장점: 공간을 절약하고 안전성을 향상시키며 다양한 하중에 적응합니다. 향후 동향으로는 모듈형 설계 및 스마트 재고 추적을 위한 IoT 통합이 포함됩니다.

요약하면, 캔틸레버 랙은 비정형 물품의 저장을 최적화하여 물류, 산업, 상업 분야에서 없어서는 안 될 존재입니다.