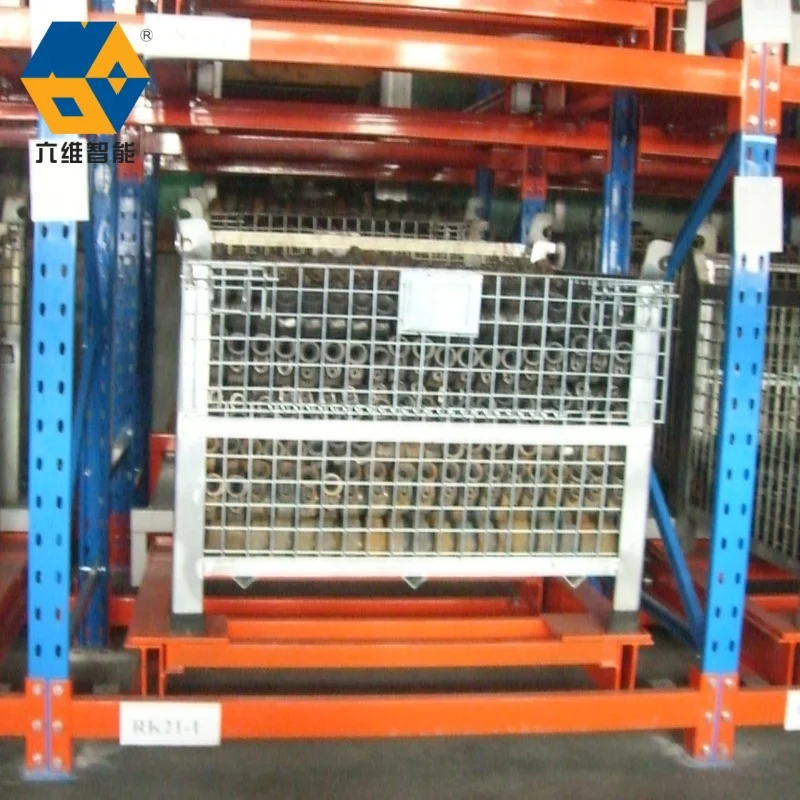

High Capacity Plastic Tubes Warehouse Storage Single Double Long Arm Steel Cantilever Rack with Heavy Duty Scales

- Overview

- Related Products

Cantilever Racking: Maximizing Storage Efficiency for Long and Bulky Items

In the world of industrial storage and warehousing, optimizing space and ensuring safe, accessible storage for diverse inventory is a constant challenge. For long, bulky, or irregularly shaped items—such as steel bars, timber, pipes, PVC tubing, furniture, or rolled materials—traditional pallet racking falls short. This is where Cantilever Racking demonstrates its unparalleled value as a specialized, robust, and highly versatile storage solution.

At its core, a cantilever racking system is elegantly simple yet ingeniously effective. It consists of vertical columns, often referred to as uprights, which are securely anchored to the floor. The defining feature is the series of horizontal arms, or "cantilevers," that project out from these columns. Unlike systems with front-to-back beams, these arms create unobstructed, open access from the side. This unique design eliminates front-column interference, allowing for the seamless loading and unloading of items that are often cumbersome to handle.

Key Advantages and Design Features:

1. Unmatched Accessibility & Space Utilization: The open-sided design is the system's greatest strength. It allows items to be stored parallel to the aisles, enabling direct side-loading with forklifts or cranes. This facilitates first-in, first-out (FIFO) or last-in, first-out (LIFO) inventory management with ease. The ability to adjust the arms vertically at incremental intervals (typically every 3 or 6 inches) provides exceptional flexibility to customize the storage layout according to the exact height of the goods, maximizing vertical cube utilization.

2. Strength and Durability: Engineered for heavy-duty performance, cantilever racking is built from high-grade structural steel. The columns are designed to handle significant cantilevered loads, often reinforced with bracing at the top and back. Arms are securely attached to the columns using robust locking mechanisms and are available in various lengths and load capacities to suit specific needs, from light-duty warehouse storage to heavy industrial applications.

3. Safety and Stability: A well-designed system prioritizes safety. Features include safety locks on arm connections to prevent accidental dislodging, column protectors (guards) at the base to shield against forklift impacts, and the option to add rear braces or wall ties for enhanced stability. Proper installation and adherence to load capacity ratings are fundamental to safe operation.

4. Versatility in Configuration: Cantilever systems can be configured as single-sided (against a wall) or double-sided (back-to-back, forming a freestanding aisle). This adaptability makes them suitable for various facility layouts. They are ideal for both indoor warehouses and, when appropriately coated for corrosion resistance, outdoor storage yards.

Ideal Applications:

The system shines in industries like lumber and building materials, metal fabrication and distribution, plumbing and electrical suppliers, furniture manufacturing and storage, plastic and tubing industries, and machinery and parts warehouses. Any environment that deals with lengthy stock finds a reliable partner in cantilever racking.

In conclusion, cantilever racking is not just another shelf; it is a purpose-engineered storage philosophy. It transforms the challenge of storing awkward, long-handled items into an opportunity for superior organization, optimized space usage, and improved operational workflow. By investing in a cantilever system, businesses gain a durable, flexible, and safe infrastructure that directly contributes to enhanced inventory control, productivity, and overall warehouse efficiency. When your inventory profile demands specialized handling, cantilever racking stands out as the definitive, high-performance solution.