Sistem industrial de stocare cu braț reglabil Nova Wholesale, din oțel cu protecție anticorozivă Ce, rastel cu consolă rezistent

- Prezentare generală

- Produse conexe

Scenarii de aplicare ale rafturilor cu consolă în depozitarea modernă

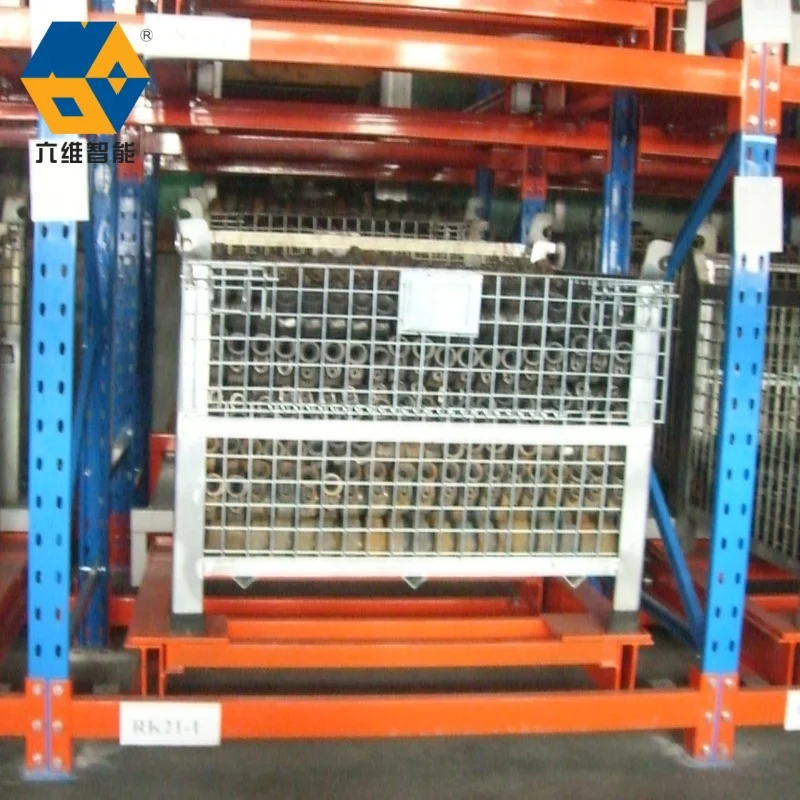

Suport Cantilever este o soluție de stocare foarte specializată și eficientă, proiectată pentru manipularea articolelor lungi, voluminoase sau cu forme neregulate, care nu pot fi stocate ușor pe rafturile clasice pentru paleți. Designul său distinctiv, care include coloane verticale și brațe lungi proiectante, fără obstacole în față, oferă o accesibilitate și flexibilitate fără egal. Acest lucru îl face un activ indispensabil în numeroase industrii.

Una dintre principalele aplicații este în industria oțelului și a metalelor. Barele, tuburile, conductele și foile metalice sunt de obicei lungi, grele și necesită manipulare atentă. Rafturile consolă permit stocarea acestor materiale în poziție orizontală, fiind susținute în siguranță de brațele reglabile. Această configurație previne îndoirea sau deteriorarea, permite identificarea ușoară vizuală a stocurilor și facilitează încărcarea laterală directă cu macarale sau transpalete, optimizând semnificativ procesul de depozitare și recuperare.

În mod similar, sectorul lemnului și cherestelei utilizează pe scară largă acest sistem. Stocarea scândurilor lungi din lemn, grinzi și produse panelate reprezintă o provocare spațială. Sistemele de stocare în consolă organizează aceste articole după tip, dimensiune și calitate, în stivuire verticală. Designul deschis dinspre culoar simplifică selectarea unor anumite piese fără a fi nevoie să mutați întregi pachete, reducând timpul de muncă și riscul de accidente asociate grămezilor instabile.

Sistemul este la fel de valoros pentru producătorii și distribuitorii de conducte din plastic și PVC. Aceste produse lungi, cilindrice, pot fi dificil de gestionat în cantități mari. Rafurile consolă facilitează o stocare organizată, protejând conductele de strivire și permițând numărarea ușoară a inventarului. În plus, industria construcțiilor și materialelor de construcție le utilizează pentru articole precum extrudatele din aluminiu, panourile de sticlă și materialele de finisare, susținând practicile de inventar just-in-time pentru proiecte mari.

În afara domeniului manufacturing, rafturile consolă își găsesc un rol esențial în centrele specializate de depozitare și distribuție care manipulează mobilier, covoare, suluri de textile sau chiar echipamente recreative precum canoe și suprafete. Posibilitatea de a ajusta înălțimea și adâncimea brațelor pe coloane oferă amenajări personalizabile ale spațiului de depozitare, care maximizează spațiul vertical și se adaptează la profilurile schimbătoare ale stocurilor.

În concluzie, rafturile consolă sunt soluția recomandată pentru gestionarea inventarului nepaletizat și de lungime mare. Avantajele lor principale — utilizarea excelentă a spațiului, accesibilitate superioară, capacitate ridicată de încărcare și adaptabilitate — se traduc în beneficii tangibile: reducerea deteriorării produselor, creșterea siguranței operaționale, îmbunătățirea controlului asupra stocurilor și eficiență generală în depozitare. Oferind un spațiu dedicat și organizat pentru articolele voluminoase, acestea elimină dezordinea și formează baza unei operațiuni logistice eficientizate în diverse medii industriale și comerciale.