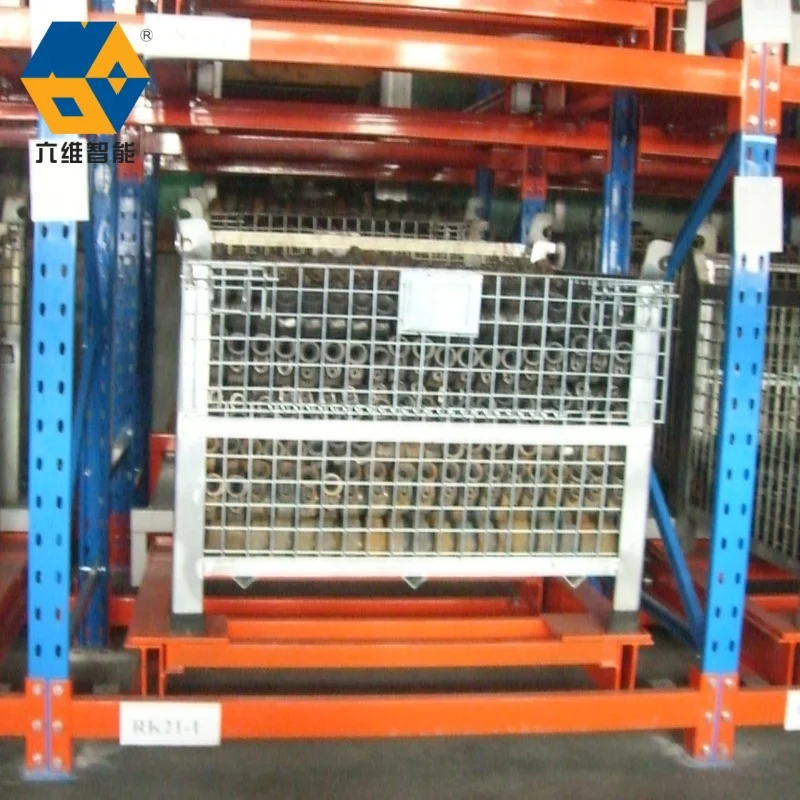

ระบบชั้นวางคลังสินค์เหล็กอุตสาหกรรมทนทาน เหล็กเดี่ยวและคู่แขนแบบคานเดี่ยวสำหรับจัดเก็บท่อ

ชั้นวางแบบคานตีนอึ่งเป็นโซลูชันการจัดเก็บที่ออกแบบมาเฉพาะสำหรับสิ่งของที่มีความยาว มีขนาดใหญ่ หรือมีรูปร่างไม่สมมาตร ซึ่งไม่สามารถจัดเก็บได้อย่างมีประสิทธิภาพบนชั้นวางพาเลทแบบดั้งเดิม ด้วยการออกแบบด้านหน้าเปิดแบบพิเศษที่มีคานยื่นออกมาจากเสาแนวตั้ง ทำให้ชั้นวางเหล่านี้มีความยืดหยุ่นสูงสุดสำหรับอุตสาหกรรมที่ต้องการการจัดเก็บที่ปรับเปลี่ยนได้ ด้านล่างนี้ เราจะกล่าวถึงพื้นที่การใช้งานหลัก ข้อดี และการใช้งานเฉพาะด้านอุตสาหกรรมของชั้นวางแบบคานตีนอึ่ง

- ภาพรวม

- ผลิตภัณฑ์ที่เกี่ยวข้อง

- ประสิทธิภาพการใช้พื้นที่: ลดความจำเป็นในการมีทางเดินหลายช่อง ช่วยเพิ่มความหนาแน่นในการจัดเก็บได้สูงสุดถึง 30%

- ความสะดวกสบาย สินค้ามองเห็นและเข้าถึงได้จากด้านใดด้านหนึ่ง ทำให้กระบวนการหยิบสินค้าเร็วขึ้น

- สามารถปรับแต่งได้: ความสูงและความลึกของแขนชั้นวางสามารถปรับได้ (โดยทั่วไป 3–10 ฟุต) เพื่อรองรับขนาดผลิตภัณฑ์ที่หลากหลาย

- ความทนทาน: ผลิตจากเหล็กทนทานหนาพิเศษพร้อมเคลือบสังกะสี ป้องกันการกัดกร่อนในสภาพแวดล้อมที่มีความชื้นสูง

- การผสานรวมระบบอัตโนมัติ: การใช้ชั้นวางแบบแคนทีลีเวอร์ร่วมกับแขนหุ่นยนต์หรือระบบติดตามด้วย RFID เพื่อจัดการสินค้าคงคลังอย่างชาญฉลาด

- การออกแบบแบบโมดูลาร์: ชิ้นส่วนน้ำหนักเบา ไม่ต้องใช้สลักเกลียว สำหรับการปรับเปลี่ยนอย่างรวดเร็วในคลังสินค้าที่มีการเปลี่ยนแปลงบ่อย

- ความยั่งยืน: การผลิตจากเหล็กรีไซเคิลและระบบไฟฟ้าประหยัดพลังงาน เพื่อการดำเนินงานที่เป็นมิตรต่อสิ่งแวดล้อม

แนวทางการใช้งานชั้นวางแบบแคนทีลีเวอร์ในคลังสินค้าและโลจิสติกส์ยุคใหม่

1. การใช้งานหลัก

A. วัสดุก่อสร้างและวัสดุอาคาร

ชั้นวางแบบคานยื่นเหมาะอย่างยิ่งสำหรับการจัดเก็บวัสดุก่อสร้างที่มีความยาว เช่น เหล็กเส้น ท่อ ไม้แปรรูป และท่อพีวีซี โครงสร้างแบบเปิดของชั้นวางช่วยให้สามารถโหลดหรือถอดสินค้าได้ง่ายด้วยรถโฟล์คลิฟต์หรือเครน ลดเวลาในการจัดการ ตัวอย่างเช่น บริษัทรับเหมาก่อสร้างใช้ชั้นวางเหล่านี้เพื่อจัดเรียงเหล็กเสริมตามขนาด ทำให้เพิ่มประสิทธิภาพในพื้นที่ก่อสร้าง

ข. อุตสาหกรรมโลหะและพลาสติก

ผู้ผลิตแผ่นโลหะ แท่งโลหะ หรือผลิตภัณฑ์อัดรีดพลาสติก พึ่งพาชั้นวางแบบคานยื่นในการจัดเก็บวัตถุดิบและสินค้าสำเร็จรูป แขนชั้นวางที่ปรับระดับได้สามารถรองรับวัสดุที่มีความยาวและน้ำหนักแตกต่างกัน ช่วยเพิ่มประสิทธิภาพการใช้พื้นที่ในโรงงาน

ค. อุตสาหกรรมยานยนต์และอากาศยาน

ในภาคอุตสาหกรรมเหล่านี้ ชั้นวางแบบคานยื่นใช้สำหรับจัดเก็บชิ้นส่วนขนาดใหญ่ เช่น ท่อไอเสีย ปีกอลูมิเนียม หรือชิ้นส่วนแชสซี ความทนทานของชั้นวาง (โดยทั่วไปรองรับน้ำหนักได้ 1,000–5,000 ปอนด์ต่อแขน) ทำให้มั่นใจได้ถึงความปลอดภัยในการจัดการสินค้าหนัก และยังช่วยให้ทางเดินไม่ถูกขวางกั้น เพื่อให้เครื่องจักรเคลื่อนที่ได้อย่างสะดวก

ง. การจำหน่ายปลีกและส่ง

เฟอร์นิเจอร์ พรม และท่อระบบปรับอากาศมักจัดเก็บบนชั้นวางแบบคานโหนในคลังสินค้าขายส่ง ซึ่งออกแบบให้สามารถเติมสินค้าด้านหน้าได้ ทำให้หมุนเวียนสต็อกได้อย่างรวดเร็วและลดความเสียหายขณะหยิบสินค้า

2. ข้อได้เปรียบเหนือชั้นวางแบบทั่วไป

3. นวัตกรรมเฉพาะอุตสาหกรรม

A. การปรับใช้สำหรับห้องเย็น

ในอุตสาหกรรมแปรรูปอาหารหรือโลจิสติกส์ยา ชั้นวางแบบคานโหนที่มีแขนทำจากสแตนเลสจะป้องกันสนิมและทนต่ออุณหภูมิต่ำ เหมาะอย่างยิ่งสำหรับจัดเก็บสินค้าแช่แข็งหรือท่อทางการแพทย์

B. คลังสินค้าแบบชั้นสูง

สำหรับสถานที่ที่มีพื้นที่แนวตั้ง ระบบแคนทีลีเวอร์สามารถใช้งานได้สูงถึง 30 ฟุตขึ้นไป เมื่อรวมเข้ากับโครงชั้นลอยหรือระบบการจัดเก็บอัตโนมัติ

C. การจัดเก็บกลางแจ้ง

รุ่นชุบสังกะสีหรือเคลือบผงถูกใช้ภายนอกอาคารเพื่อจัดเก็บท่อระบายน้ำหรือแผงโซลาร์เซลล์ โดยสามารถทนต่อความเสียหายจากสภาพอากาศได้

4. แนวโน้มในอนาคต

สรุป

ชั้นวางแบบแคนทีลีเวอร์มีความจำเป็นอย่างยิ่งต่ออุตสาหกรรมที่ต้องจัดการกับสินค้าขนาดยาวหรือหนัก โดยนำเสนอความยืดหยุ่น ความทนทาน และการใช้พื้นที่อย่างมีประสิทธิภาพที่ไม่มีใครเทียบได้ เมื่อโลจิสติกส์พัฒนาไปสู่ระบบอัตโนมัติและความยั่งยืน ชั้นวางเหล่านี้จะยังคงปรับตัวต่อไป ทำให้บทบาทของพวกมันมั่นคงยิ่งขึ้นในห่วงโซ่อุปทานสมัยใหม่