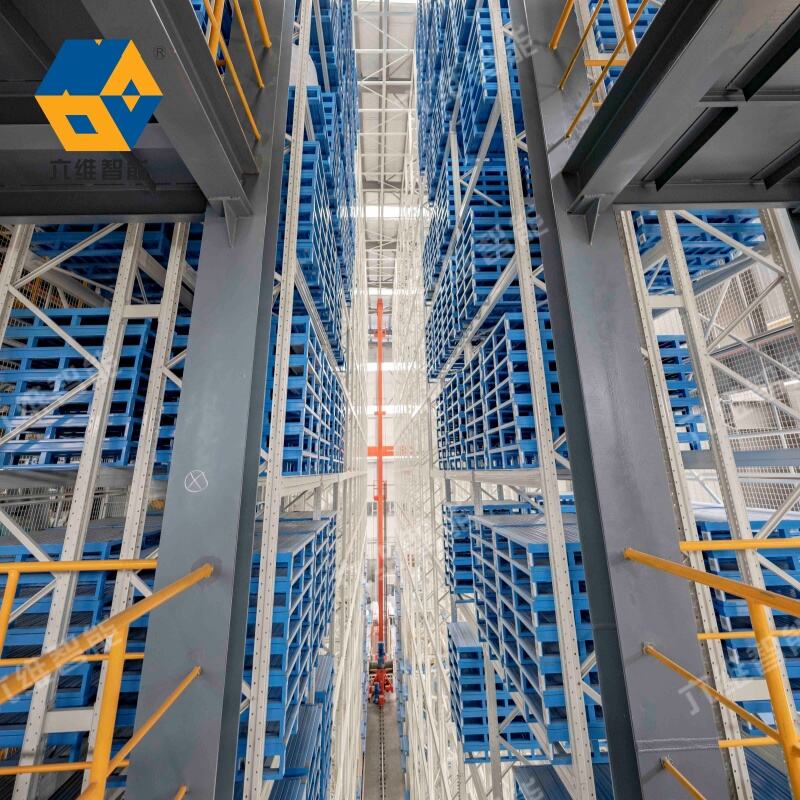

multi tier racking system

A multi tier racking system represents a revolutionary approach to warehouse storage optimization, combining vertical space utilization with efficient inventory management. This sophisticated storage solution enables businesses to maximize their warehouse capacity by creating multiple levels of storage within the same footprint. The system typically consists of robust steel structures that can extend up to several stories high, with each level featuring dedicated picking areas and storage zones. Advanced engineering ensures structural integrity while maintaining accessibility through integrated staircases, elevators, and conveyor systems. The design incorporates various safety features including anti-collapse mechanisms, load distribution systems, and fire protection measures. These systems can be customized to accommodate different product sizes, weights, and storage requirements, making them suitable for diverse industries from e-commerce to manufacturing. The integration of modern warehouse management systems allows for real-time inventory tracking across all levels, enhancing operational efficiency. Temperature control and ventilation can be implemented throughout the structure, making it suitable for storing sensitive materials. The system's modular nature allows for future expansion and reconfiguration as business needs evolve.