Introduction to ASRS Warehouses

Defining Automated Storage and Retrieval Systems

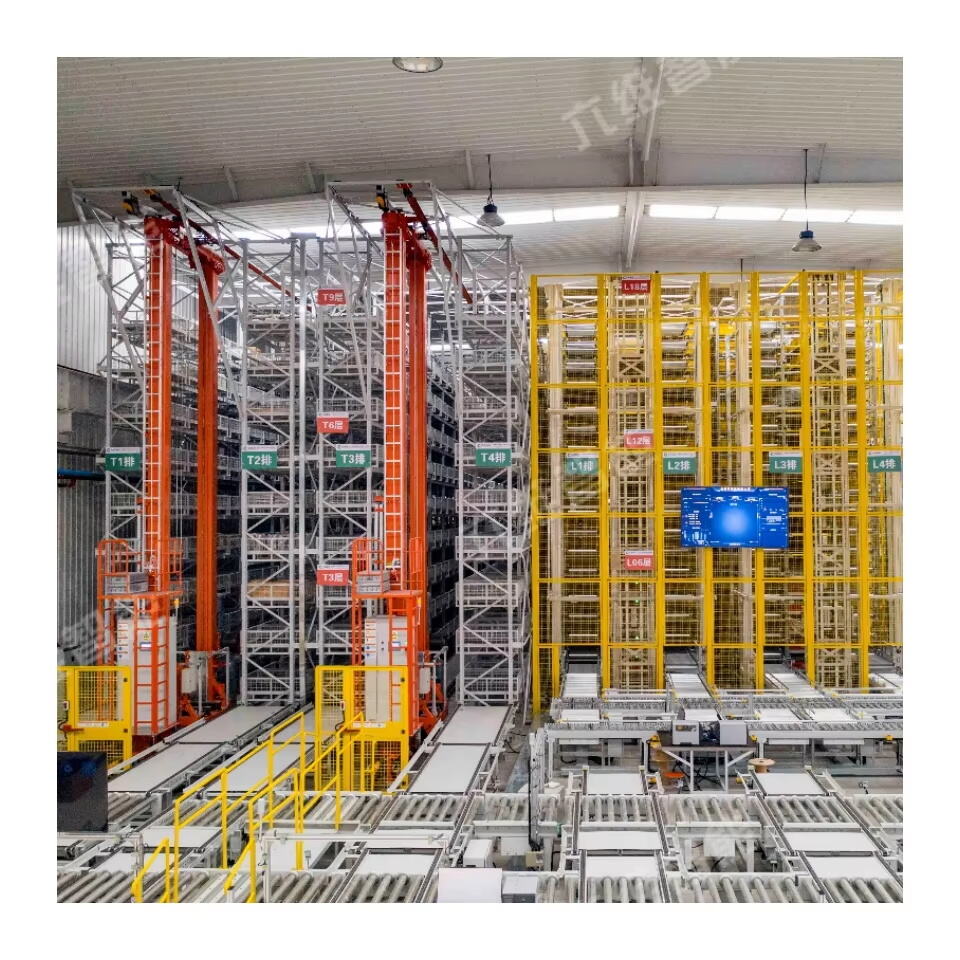

ASRS systems represent a major leap forward for warehouse operations, helping companies manage their inventory better while making day-to-day tasks much smoother. These setups combine robotic arms, specialized software programs, and moving belts to get items stored and retrieved faster than traditional methods allow. The main goal here is simple but powerful: cut down on human labor requirements while getting more done in less time across warehouse floors. For businesses dealing with high volume storage needs, especially those in retail or manufacturing sectors, implementing ASRS can mean significant savings over time as well as improved accuracy rates when tracking stock levels throughout facilities.

The Evolution of Warehouse Automation

Warehouse automation has changed quite a bit since those early days when workers moved everything by hand back during the industrial revolution era. Things gradually got mechanized first, then eventually we ended up with today's sophisticated automated systems. These days, tech stuff like RFID tags, Internet of Things devices, and artificial intelligence are really making a difference in how ASRS systems work, basically supercharging what they can do while running smoother too. Looking at the market right now, folks are betting big on these ASRS technologies. Industry analysts predict around 12% compound annual growth over the next few years as companies keep investing. Why? Because businesses across warehouses and logistics want faster turnaround times and pinpoint accuracy in their operations more than ever before.

Why Modern Logistics Demands ASRS Solutions

With online shopping growing so fast these days, warehouses just cant keep up with what customers expect anymore. Automated Storage and Retrieval Systems or ASRS have become really important for companies trying to stay ahead. These systems make things run smoother and reduce errors, which matters a lot when competing in today's tight logistics market. Companies face all sorts of problems when they try to scale operations while dealing with unpredictable demand spikes. That's why flexible warehouse setups matter so much now. The good news is ASRS technology fits right into existing logistics networks. It helps operations bounce back from disruptions and adjust quickly when market conditions change unexpectedly.

How ASRS Technology Works

Key Components: Robots, Conveyors, and Software

Automated Storage and Retrieval Systems (ASRS) depend on several key parts working together inside warehouses. Robots play a big role here, handling everything from grabbing products off shelves to moving them around the facility, which boosts both speed and accuracy in operations. Conveyor belts also make a difference by keeping items moving smoothly through different areas of the warehouse, cutting down on bottlenecks during busy periods. Software is another critical element, acting as the brain behind all this machinery. It ties everything together, constantly updating information about stock levels and tracking where things go, so managers can see what's happening in real time without having to walk through every aisle themselves. Getting all these pieces to work well together isn't always easy though, requiring careful planning and regular maintenance checks to keep everything running without hiccups.

Operational Flow: From Storage to Retrieval

ASRS operations kick off when products roll into the warehouse for processing. Scanning takes place right away so the system knows exactly what it's dealing with. After scanning, items get sorted out based on type and size before being put away in spots chosen by complex ASRS software calculations that aim for quick access later on. Orders trigger automatic action too. Once someone places an order, robotic arms or driverless carts jump into motion, grabbing whatever needs shipping from wherever it was stored. The whole setup works pretty well actually. Less mistakes happen because everything follows strict protocols, orders go out faster than traditional methods allow, which explains why most big warehouses have switched to some form of ASRS these days for their day to day operations.

Integration with Warehouse Management Systems (WMS)

ASRS systems work well together with Warehouse Management Systems (WMS) to give warehouses one place to manage everything. When these systems connect, it helps keep track of what's in stock, where products go, and how work gets done around the facility. The WMS software talks back and forth with ASRS equipment, making changes on the fly based on current data and analysis. This means warehouses can adapt quickly when things change or inventory levels drop unexpectedly. Smart businesses know this setup boosts productivity while cutting down on manpower expenses. Many warehouse managers have found that getting these systems talking to each other makes their whole operation run smoother day after day.

Types of ASRS Systems

Unit-Load ASRS for Palletized Goods

Unit load ASRS systems work great for handling big items and pallets, so they fit well in warehouses that deal mostly with bulk products. The real advantage comes from making good use of vertical space instead of just spreading out horizontally, something many traditional warehouses struggle with. Most setups include things like pallet shuttles running along rails and automatic cranes that grab and move loads without much human intervention. For facilities storing tons of heavy stuff day after day, these systems make all the difference when it comes to getting inventory in and out quickly. Warehouse managers who have switched to this setup often report significant improvements in throughput while maintaining accurate stock levels even during peak seasons.

Mini-Load Systems for Small Item Handling

Mini load systems work best in warehouses dealing with lots of small parts, which helps speed things up when picking and storing goods. The systems come with compact shuttles and special tools that grab items from shelves much faster than traditional methods. Retailers and big distribution hubs find these mini load automated storage systems really helpful when they have thousands of different small stock keeping units (SKUs) to manage. When operations get streamlined for handling tiny components or packages, warehouses see better accuracy rates and quicker turnaround times. That's why so many facilities with varied product ranges turn to these specialized systems for their day to day operations.

Vertical Lift Modules (VLM) for Space Optimization

Vertical Lift Modules, or VLMs as they're often called, offer warehouses a way to make better use of their space by taking advantage of the vertical dimension rather than spreading out horizontally. The system works by storing items in trays that move up and down inside the unit, which cuts down on how much floor area is needed while still allowing workers to grab what they need quickly. This kind of setup really shines in places where there just isn't enough room to expand outward, like older buildings or urban locations with high rent costs. Companies find these systems boost their storage capacity dramatically compared to traditional methods. For businesses trying to grow without moving to bigger facilities, VLMs represent a smart investment that pays off in both space savings and operational efficiency.

Carousel-Based ASRS for Rapid Access

Carousel systems really boost how fast workers can get their hands on items thanks to that spinning motion that brings stuff right to where they need it. These systems work great in places where people constantly grab the same items over and over again. Carousel Automated Storage and Retrieval Systems handle all sorts of sizes from tiny parts to bigger boxes, which means they fit pretty much any warehouse setup. Companies that want better access to stock while cutting down on time spent searching will find carousel systems a good investment. Warehouse managers report seeing noticeable improvements in day to day operations once these systems are installed, making the whole picking process smoother and faster across the board.

Benefits of Implementing ASRS

Maximizing Vertical Space Utilization

ASRS systems really expand what warehouses can store by making good use of the space above floor level. Warehouses that install these systems often go for taller shelves, which means they can fit way more stuff in the same footprint. When companies maximize vertical space instead of spreading out horizontally, they save money on rent and day-to-day running costs. The best part? Products stay accessible even when stacked high, so workers don't have to dig through mountains of inventory to find what they need. Safety remains intact too since modern ASRS setups include features that prevent accidents during retrieval.

Reducing Labor Costs and Human Error

When companies put in place ASRS systems, they cut down on the need for so much manual work. This means saving money on labor expenses while also cutting down those annoying little errors people tend to make. Research shows warehouse accuracy goes way up with these systems in place sometimes hitting around 99% accuracy rates. That makes a big difference when picking orders since fewer items get mixed up or misplaced. Without all the repetitive handwork, employees can spend their time on things that really matter for business growth instead of just moving boxes around all day long. The whole operation runs smoother too because there's less back and forth between different parts of the facility.

Enhancing Inventory Accuracy and Traceability

ASRS tech comes with advanced tracking capabilities that really nail down where inventory is located and how much there actually is. When warehouses can track their goods this precisely, they manage stock much better. They know when to restock before shelves go empty, which means fewer situations where customers walk away because something's out of stock. The real time data from these systems gives managers actual numbers to work with instead of guessing games. Warehouse staff make smarter choices about moving products around, which cuts down on wasted time and effort. Overall operations run smoother day to day, though it does take some getting used to for teams transitioning from older methods.

Scalability for Growing Business Needs

ASRS systems grow right along with expanding businesses, giving warehouses the ability to handle bigger inventories and process more orders as needed. When companies need to upgrade their storage capabilities, they can simply add new parts to existing ASRS setups instead of tearing everything down and starting fresh. This makes sense for operations facing changing market conditions or seasonal fluctuations. The real advantage here is that businesses stay ready for whatever comes next without having to spend a fortune on brand new equipment every time demand spikes.

Industries Transformed by ASRS

E-Commerce and Omnichannel Fulfillment

E-commerce businesses need fast shipping and accurate orders, which is where Automated Storage and Retrieval Systems (ASRS) come in handy. These systems really boost both speed and accuracy, something absolutely necessary when dealing with all those orders coming in every day plus keeping customers happy. Retailers using omnichannel approaches find ASRS particularly useful because it helps track inventory everywhere from online stores to physical locations, making sure everything works together smoothly for shoppers. Some real world examples show companies that implemented ASRS saw their order processing times jump by about half. That kind of improvement makes a huge difference in daily operations, cutting down on errors and saving time throughout the whole supply chain process.

Automotive Manufacturing and Parts Logistics

Automakers depend on ASRS systems to keep their parts organized and ready when needed on the assembly line floor. These automated storage and retrieval setups help factories avoid expensive downtime because they can grab parts without human intervention, which makes everything run smoother day after day. Studies have shown that companies using ASRS in their supply chain operations often see lead times shrink around 30%. That kind of improvement means fewer delays and happier customers waiting for their cars. Managing inventory precisely and getting components out fast matters a lot in an industry where every minute counts during production runs.

Pharmaceuticals: Precision in Cold Chain Storage

Automated Storage and Retrieval Systems (ASRS) are really important in the drug manufacturing world, especially when dealing with medicines that need strict temperature management. These systems keep everything stored at just the right temps, which helps meet all those tough regulations from agencies like the FDA. What makes ASRS so valuable is how they automate the whole process, cutting down on mistakes when dispensing medications. We're talking about fewer mix-ups between different drugs or incorrect dosages. For companies handling vaccines or biologics that must stay within narrow temperature bands during transport and storage, this kind of precision isn't just nice to have it's basically table stakes these days in the pharma business.

Aviation and Heavy Machinery Components

ASRS systems play a key role in storing heavy machinery parts safely and efficiently within the aviation sector. These specialized setups are designed specifically for aviation materials' unique weight limits and size constraints, which makes them handle properly without damage. The main advantage? Quick access during maintenance work and aircraft assembly when every minute counts for keeping planes flying on schedule. With reliable performance and accurate positioning capabilities, ASRS can manage those big, bulky components that otherwise would be difficult to store and retrieve. This kind of system helps aviation companies maintain their strict safety protocols while also boosting overall efficiency across operations.

For more information about ASRS Warehouse solutions and how they are revolutionizing various industries, you can explore detailed evidence in recent market studies.

FAQ

What are Automated Storage and Retrieval Systems (ASRS)?

ASRS are advanced systems that enhance inventory management and warehouse operations using robotics, software, and conveyors to expedite processes and optimize space.

How do ASRS systems integrate with existing warehouse operations?

ASRS systems integrate with Warehouse Management Systems (WMS) to maintain inventory visibility, track product movements, and optimize workflow based on real-time analytics.

What types of ASRS systems are available?

Types of ASRS systems include Unit-Load ASRS for large items, Mini-Load Systems for small items, Vertical Lift Modules for space optimization, and Carousel systems for rapid access.

What industries benefit from ASRS technology?

Industries such as e-commerce, automotive, pharmaceuticals, and aviation have been transformed by ASRS technology, each benefiting from enhanced efficiency and precision.

What are the key benefits of implementing ASRS?

Benefits include maximizing vertical space, reducing labor costs and errors, enhancing inventory accuracy, and scalability for growing business needs.