rack warehouse

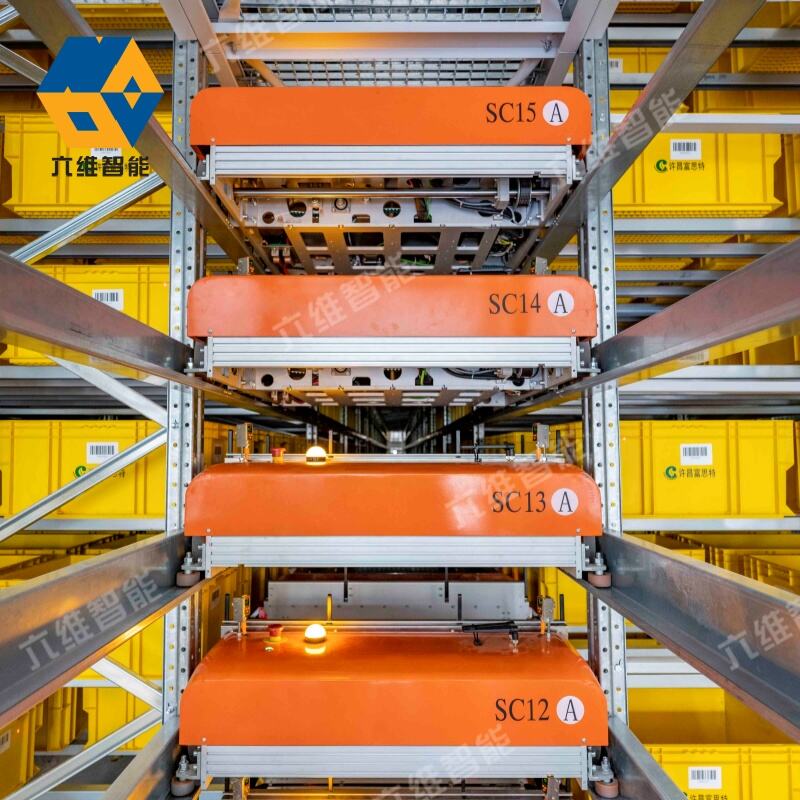

A rack warehouse represents a sophisticated storage solution that maximizes vertical space utilization through systematic organization of goods on multiple levels of racking systems. These modern facilities integrate advanced storage equipment with intelligent management systems to create an efficient, accessible, and organized storage environment. The fundamental structure consists of heavy-duty steel racks arranged in systematic aisles, allowing for both manual and automated retrieval systems. The warehouse incorporates various rack types, including selective pallet racks, drive-in racks, and push-back racks, each serving specific storage needs. Modern rack warehouses feature state-of-the-art inventory management systems, often equipped with barcode scanners, RFID technology, and warehouse management software that ensures precise tracking of stored items. The facility's design prioritizes optimal space utilization while maintaining safe and efficient access to all storage locations. These warehouses commonly employ automated storage and retrieval systems (AS/RS), conveyor systems, and advanced picking technologies to enhance operational efficiency. The integration of these technologies enables real-time inventory tracking, reduced handling errors, and improved order fulfillment accuracy.