cijene palačnika za pohranu paleta s vožnjom

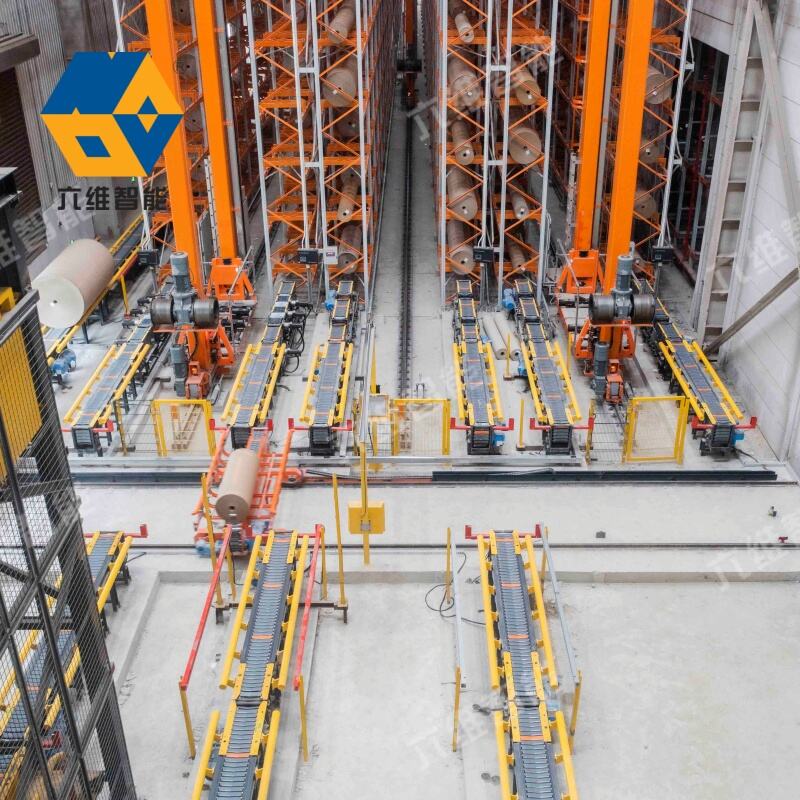

Cijene pločnog skladišnog sustava s ulazom na vožnju predstavljaju ključnu razmatranicu u savremenoj upravi skladišta, pružajući ekonomično rješenje za pohranu koje maksimizira korištenje prostora. Ovaj sustav pohrane omogućuje da se forklift vozilo direktno uvozi u strukturu regala, što omogućuje visokogustativnu pohranu sličnih proizvoda. Struktura cijena obično se mijenja ovisno o faktorima poput visine sustava, dubine i nosivosti opterećenja, s opcijama koje raspuštaju od osnovnih konfiguracija do naprednih automatskih sustava. Savremeni sustavi pločnog skladišta s ulazom na vožnju uključuju sigurnosne značajke poput vodičkih račica, nosača strukturne podrške i teških okvira dizajniranih za otpornost na česte interakcije s forkliftom. Dizajn sustava tipično prilagođava upravljanje inventarom po principu posljednji-ušao-prvi-izašao (LIFO), što ga čini posebno prikladnim za masovnu pohranu nepropadljivih roba ili proizvoda s sličnim rokove trajanja. Tehnološki napretak je uveo poboljšanu trajnost kroz poboljšane materijale i strukturne dizajne, istovremeno održavajući konkurentne cijene za tvrtke različitih veličina. Prilagodljivost sustava omogućuje prilagođavanje specifičnim dimenzijama skladišta i zahtjevima za pohranu, s cijenama koje odražavaju složenost i razinu instalacije.