הבנת דרישות העומס בתאגיד מאגרים

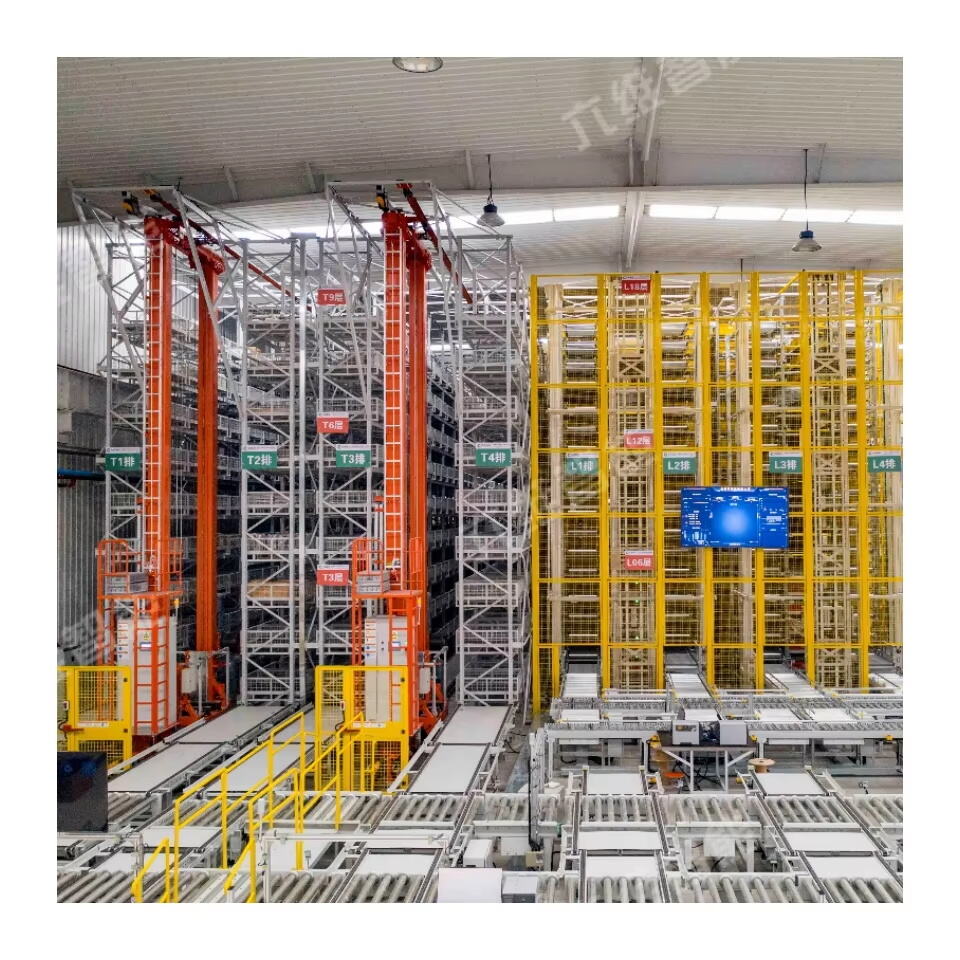

בבתי מלאכה מודרניים ותאגיד מאגרים, קביעת מדף כבד נפח העומס הוא קריטי גם ליעילות התפעולית וגם לבטחה. בין אם אתה מנהל מרכז הפצה גדול או מארגן מפעל ייצור, היכולת לאחסן ולגשת לחומרים בצורה בטוחה תלויה לחלוטין בבחירת מדשאות עם נפח עומס מתאים. מדריך מקיף זה יחקור את כל מה שעליכם לדעת על מדף כבד נפח העומס, ולוודא שתקבלו החלטות מושכלות בפ regard לפתרונות האחסון שלכם.

היבטים בסיסיים של נפח העומס

עקרונות התפלגות משקל

בעת בחינה בקיבולת המטען של מדפים כבדים, הבנת התפלגות המשקל היא בעלת חשיבות מכריעה. כל מערכת מדפים נועדה להתמודד עם דפוסי מטען מסוימים, והתפלגות מתאימה מבטיחה ביצועים אופטימליים. סך הקיבולת אינו תלוי רק במטען המקסימלי - אלא גם באופן שבו המטען מפוזר במבנה כולו. התפלגות אחידה מאפשרת לרוב קיבולת כוללת גבוהה יותר, בעוד מטען לא אחיד עשוי להצריך הפחתת הגבול העליון של המשקל.

מערכות מדפים מודרניות משולבות עקרונות הנדסיים מתוחכמים כדי למקסם את יכולת הנשיאה תוך שמירה על שלמות מבנית. היחסים בין רמות הבולמות, מסגרות העמידה ותומכים צולבים כוללים תפקיד חשוב בקביעת קיבולת המטען הסופית. המהנדסים מתחשבים גם במשקלים סטטיים ודינמיים, ומביאים בחשבון לא רק את משקל הפריטים האגורים אלא גם את הכוחות הפועלים במהלך פעולות טעינה ופריקה.

השפעת החומר והבנייה

החומרים המשמשים בבניית מדפים משפיעים באופן משמעותי על כושר העומס של מדפים כבדים. פלדה איכותית, במיוחד אלו בעלות תכונות מתכות מתקדמות, מספקת יחס חוזק-משקל מעולה. עובי הפלדה, המכונה מד, משפיע ישירות על יכולת נשיאת העומס של הקורות והאנכים כאחד.

תהליכי ייצור, כולל טכניקות לחיצת ברגים ויישור ציפוי, גם הם תורמים משמעותית לנקודות הכוח הסופיות. בקרת איכות בתקופת הייצור מבטיחה עקביות ביכולת לתמוך במשקל בכל הרכיבים. השימוש בחיבורים מחוזקים ובבסיסים בעלי עיצוב מדויק תורם לחיזוק שלמות מבנית כוללת.

תקנים לבטחון והסכמה

דרישות רגולטוריות

מערכות אחסון תעשיותיות חייבות לעמוד בדרישות ביטחון חמורות הנוגעות ליכולת נטל של מדפים כבדים. ארגונים כגון OSHA וגופים בינלאומיים אחרים מספקים הנחיות מקיפות בנוגע לבטיחות מדפים וניהול נטל. תקנות אלו מכסות את כל התחומים החל מהתקנה ראשונית ועד תחזוקה מתמדת ובדיקות שוטפות.

התאמה לתקנות אלו אינה רק עניין של עמידה בדרישות חוקיות - אלא עניין של שמירת ביטחון במקום העבודה ו הגנה על מלאי בעל ערך. ביקורות תקופתיות של נטל והתקנים מבניים עוזרות לשמור על שלמות המערכת ולזהות בעיות פוטנציאליות לפני שהן הופכות לאיום חמור.

שקול מקדם הבטחה

מהנדסים מקצועיים משלבים גורמי בטיחות בחישובי קיבולת העומס של מתלים כבדים. גורמים אלה מספקים מרווח בטיחות מעבר לקיבולת המדורגת, תוך התחשבות בתנאים שונים בעולם האמיתי שעשויים להשפיע על הביצועים. הבנה וכיבוד של מרווחי בטיחות אלה חיוניים לאמינות המערכת לטווח ארוך.

תנאי סביבה, כמו תנודות טמפרטורה, פעילות סייסמית, וחשיפה לאלמנטים קורוזיביים, עלולים להשפיע על יכולת הנשיאה לאורך זמן. מקדמים לאבטחה מתאימים תורמים להבטיח שהמערכות של המדפים ישמרו על שלמותן גם בתנאים פחות אידיאליים.

יישום ואופטימיזציה

תכנון קיבולת עומס

תכנון יעיל של עוצמה של מדפים כבדים מתחיל בניתוח מקיף של צורכי האחסון הנוכחיים והעתידיים. זה כולל התחשבות לא רק במשקל הפריטים המאוחסנים אלא גם בממדיהם, דרישות הגישה ויחס הסיבוב. כלים ותוכנות תכנון מתקדמות יכולות לעזור באופטימיזציה של תצורת המדפים ובייעול ניצול העוצמה.

עבודה עם ספקי פתרונות לאחסון מנוסים מבטיחה שהמערכת שלך של מדפים תתוכנן כראוי בהתאם לצרכים הספציפיים שלך. הם יכולים לעזור לזהות צווארים בקבוק, להציע תצורות אופטימליות, ולוודא שהמערכת שלך עומדת הן בדרישות הנוכחיות והן בפוטנציאל הצמיחה העתידי.

פרוטוקולים לתיקון והתקנה

התקנה נכונה היא קריטית להשגת עוצמה המתוכננת של מדפים כבדים. זה כולל ודאות שרצפות רמות, מיקום נכון של עוגנים, וalinemenation מדויקת של כל הרכיבים. צוותי התקנה מקצועיים משתמשים בכלים ובשיטות מיוחדים כדי לוודא שכל רכיב ממוקם ומאובטח בצורה תקינה.

תכניות תחזוקה שגרתיות עוזרות לשמר את העומס המתוכנן לאורך חיי המערכת. התכניות כוללות בדיקות תכופות, תיקון מידי של כל נזק שנעשה, והערכה מחזורית של דפוסי עומס משתנים או דרישות חדשות. תיעוד תקין של פעולות התחזוקה עוזר לעקוב אחרי ביצועי המערכת ולזהות אזורים פוטנציאליים לשיפור.

שיקולים מתקדמים וтенדנציות עתידיות

שילוב טכנולוגיה

ניהול מחסנים מודרני סובל יותר ויותר על טכנולוגיה כדי לפקח ולממש את מיטוב עוצמת המטען של המבנה. חיישני מטען, מערכות פיקוח מבניות ומנועים אוטומטיים לניהול מלאי מספקים נתונים בזמן אמת על ביצועי המערכת והשימוש בה. טכנולוגיות אלו עוזרות במניעת עומסים מיותרים ומבטיחים שימוש אופטימלי בקיבולת הזמינה.

שילובם של אלגוריתמי אינטליגנציה מלאכותית ולמידת מכונה הופך את הדרך בה אנו מתקרבים לניהול עומס במתקנים. מערכות אלו יכולות לחזות צרכים לתחזוקה, להציע התפלגות אופטימלית של עומסים, ולסייע במניעת תקלות מבניות לפני שהן מתרחשות.

קיימות ויעילות

הגישה המודרנית ליכולת נשיאה של מדפים כבדים מתחילה לשקול יותר את ההיבטים האקולוגיים והיעילות האנרגטית. הגישה כוללת שימוש בחומרים מחזוריים, יישום מערכות טיפול אנרגטיות, ועיצוב נבנה לי tốiוד שימוש במרחב. מעשנים ברורים לא רק שמזיקים פחות לסביבה אלא גם לרוב מביאים לשיפור ביעילות התפעולית ופחת הוצאות.

העתיד של מערכות אחסון תעשייתיות מצביע על שיטות מתקדמות אף יותר לניהול יכולת העומס. מדובר בפיתוח חומרים חכמים שיכולים להתאים את עצמם לעומסים משתנים, שימוש יעיל יותר במרחב האנכי, ושילוב במערכות טיפול אוטומטיות.

שאלות נפוצות

איך מחשבים את יכולת העומס של מדף כבד?

התכולה המרבית של מדף כבד מחושבת תוך התחשבות בגורמים רבים, בהם חוזק החומרים, העיצוב המבני, מקדמי ביטחון וنمטי השימוש. מהנדסים מנתחים הן את תכולת הרכיבים הבודדים והן את המערכת בכללותה, תוך הכללת שולי ביטחון ותקינות עם סטנדרטים רלוונטיים.

מה משפיע על הביצועים לטווח הרחוק של תכולת המדף?

למספר גורמים יש השפעה על הביצועים לטווח הרחוק, בהם תנאי הסביבה, דפוסי השימוש, פרקטי תחזוקה ואיכות ההתקנה המקורית. בדיקות תקופתיות, הפצה נכונה של עומס ותיקונים מידיים של כל נזק עוזרים לשמור על התכולה המתוכננת לאורך זמן.

מתי יש לעדכן את הערכת תכולת העומס?

יש reassess יכולת העומס בעת ביצוע שינויים משמעותיים בדרישות האחסון, לאחר כל נזק מבני מתרחש, במהלך שיפוצים גדולים של המתקן, או במרווחים קבועים כחלק מתכנית תחזוקה מקיפה. הערכות קבועות עוזרות להבטיח המשך פעולה בטוחה ותפקוד אופטימלי.