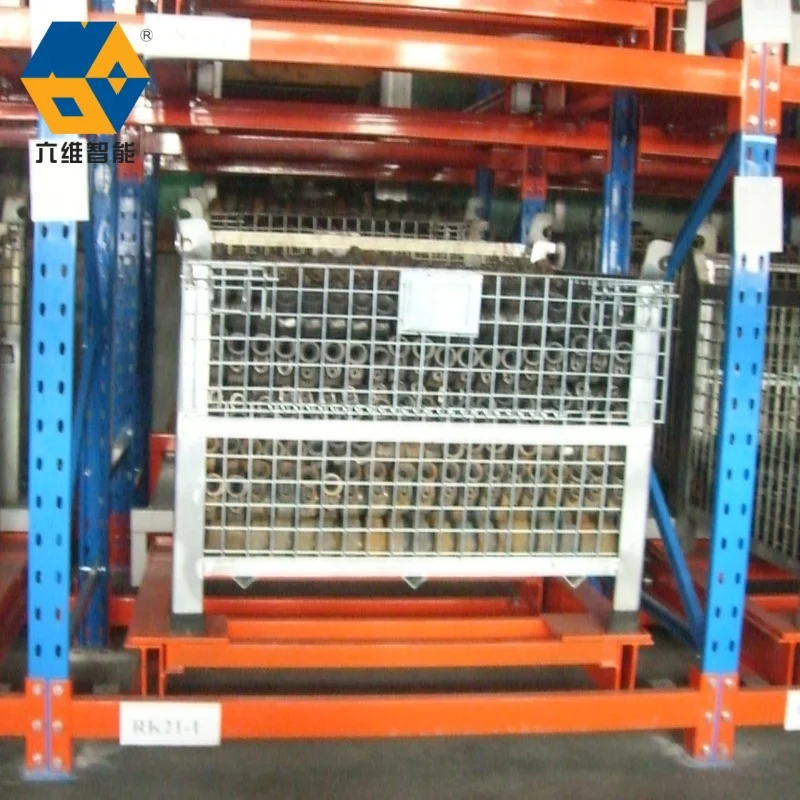

2025 New Model Cantilever Racking Storage System Cantilever Rack Heavy Duty Adjustable Single Cantilever Rack

- Overview

- Related Products

- Columns/Uprights: The vertical supports, anchored to the floor. These are heavy-duty steel posts.

- Arms: The horizontal load-bearing elements that extend from the columns. They attach via special connectors or pins and come in various lengths and capacities. Arms often have a slight upward tilt at the end to help prevent items from sliding off.

- Base Plates: Large plates at the bottom of columns that distribute the load and are bolted to the floor.

- Bracing (Optional): Diagonal or horizontal bars connecting columns, or tie rods connecting the tops of opposing columns on double-sided runs, can be added for extra stability, especially on taller systems or those carrying very heavy loads.

- Column Protectors: Optional safety barriers placed at the base of columns to prevent damage from forklift impacts.

- Item Dimensions & Weight: Length, width, height, and weight per item or per load determine the required arm length, spacing, height adjustments, and overall load capacity needed.

- Forklift Type: The reach and capabilities of the handling equipment dictate aisle widths and the feasibility of accessing certain heights.

- Building Constraints: Ceiling height, floor strength, column spacing, and existing infrastructure must be considered.

- Seismic Considerations: In earthquake-prone areas, specific bracing and anchoring requirements apply.Professional consultation and adherence to manufacturer specifications and relevant safety standards are essential during design and installation.

Cantilever Racking: The Flexible Backbone for Long, Heavy, and Awkward Items

In the world of warehousing and industrial storage, efficiency, space utilization, and safety are paramount. When dealing with long, heavy, or irregularly shaped items – think lumber, pipes, sheet metal, rolls of carpet, steel bars, or even furniture – traditional pallet racking often falls short. This is where Cantilever Racking steps in as the specialized, robust solution designed to handle exactly these challenging storage needs.

What is Cantilever Racking?

At its core, cantilever racking is a freestanding storage system characterized by its unique design: vertical columns (uprights) support horizontal arms that project outward. These arms are the defining feature. Unlike pallet racking where beams are supported at both ends, cantilever arms are typically supported only at the column end, creating a true "cantilever" structure. This open-front design provides unobstructed access along the entire length of the stored items.

Key Advantages and Features:

1. Unmatched Accessibility: The open front allows forklifts or other handling equipment (like sideloaders or cranes) direct access to load and unload items from the side. There are no cross-beams blocking the way, making it incredibly efficient for handling long materials.2. Ideal for Long & Bulky Items: Cantilever racks excel at storing items that are lengthy (often exceeding 12 feet / 4 meters), bulky, or have irregular shapes that don't fit neatly onto pallets or within the confines of standard racking bays. Common applications include construction materials (lumber, pipes, rebar), metal fabrication stock (sheet metal, bar stock, tubing), plastic extrusions, carpet rolls, doors, windows, and large furniture components.

3. High Weight Capacity: Built for heavy-duty applications, cantilever racks are engineered from robust materials, typically high-grade steel. The arms are designed to handle significant point loads. Capacities can vary greatly depending on the arm length, column height, and design specifics, but systems capable of supporting thousands of pounds (or kilograms) *per arm* are common. The columns are anchored securely to the floor for maximum stability.

4. Flexibility and Adaptability: One of the standout features is its modularity and adjustability. Arms can usually be positioned at various heights along the columns to accommodate different stock lengths and weights. The spacing between arms can also be customized. This allows for easy reconfiguration as storage needs change. Furthermore, systems can be designed as single-sided (against a wall) or double-sided (back-to-back, maximizing space).

5. Space Optimization: By storing items vertically and utilizing height effectively, cantilever racking makes excellent use of warehouse cubic space. It often provides a more efficient footprint for long items than floor stacking or alternative methods.

6. Enhanced Safety: When properly designed, installed, and loaded within capacity limits, cantilever racks provide a stable and secure storage solution. Features like base plates, anchor bolts, and sometimes rear bracing or tie rods add to the structural integrity. Clear visibility of stored items also aids in safe handling.

Components:

Design and Installation Considerations:

Proper design is crucial. Factors include:

Conclusion:

Cantilever racking is an indispensable storage solution for industries that manage long, heavy, or awkwardly shaped inventory. Its open-access design, high load capacity, and inherent flexibility make it the go-to choice for maximizing space efficiency, improving material handling workflows, and ensuring safe storage for challenging loads. If your warehouse deals with materials that defy conventional pallet racking, investing in a well-designed cantilever racking system is a strategic move towards greater operational efficiency and organization. It provides the strong, adaptable backbone needed to handle your most demanding storage requirements.