Modern warehouses face unprecedented challenges in managing inventory efficiently while meeting growing customer demands for faster delivery times. The implementation of an automated storage and retrieval system represents a transformative solution that addresses these operational complexities through advanced technology integration. These sophisticated systems combine robotics, software intelligence, and precision engineering to create warehouse environments that operate with minimal human intervention while maximizing storage capacity and retrieval accuracy.

The evolution of warehouse automation has reached a critical juncture where traditional storage methods struggle to keep pace with modern logistics demands. Companies across industries are discovering that an automated storage and retrieval system provides the technological foundation necessary to compete in today's fast-paced marketplace. This comprehensive approach to warehouse management eliminates many human error factors while delivering consistent performance metrics that support business growth objectives.

Understanding the fundamental advantages of implementing an automated storage and retrieval system requires examining both immediate operational benefits and long-term strategic value propositions. These systems integrate seamlessly with existing warehouse management software to create unified operational platforms that enhance decision-making capabilities while reducing labor dependency. The sophisticated algorithms governing these systems continuously optimize storage locations and retrieval sequences to maintain peak operational efficiency.

Core Components and Technologies

Robotic Infrastructure Systems

The robotic infrastructure forms the mechanical foundation of every automated storage and retrieval system, incorporating precision-engineered components designed for continuous operation under demanding warehouse conditions. These robotic units navigate predefined pathways with millimeter-level accuracy, utilizing advanced sensor arrays to detect obstacles and optimize movement patterns. The integration of artificial intelligence algorithms enables these robots to learn from operational patterns and adjust their behavior to maximize throughput while minimizing energy consumption.

Modern robotic systems within an automated storage and retrieval system feature modular designs that facilitate easy maintenance and component replacement without disrupting overall operations. The redundancy built into these systems ensures that individual unit failures do not compromise warehouse functionality, as remaining robots automatically redistribute workloads to maintain service levels. Advanced battery management systems provide extended operational periods between charging cycles while monitoring power consumption patterns to predict maintenance requirements.

Control Software Architecture

The control software architecture serves as the intelligent brain of an automated storage and retrieval system, coordinating complex interactions between multiple robotic units while maintaining real-time inventory visibility. This sophisticated software platform processes thousands of simultaneous requests while optimizing routing algorithms to minimize retrieval times and maximize system throughput. Machine learning capabilities enable the system to adapt to changing inventory patterns and seasonal demand fluctuations.

Integration capabilities within the control software allow seamless connectivity with enterprise resource planning systems, warehouse management platforms, and customer relationship management databases. This comprehensive data integration creates a unified operational environment where inventory movements trigger automatic updates across all connected systems. The software's predictive analytics capabilities analyze historical data patterns to forecast future storage requirements and optimize space allocation strategies.

Operational Efficiency Advantages

Space Utilization Optimization

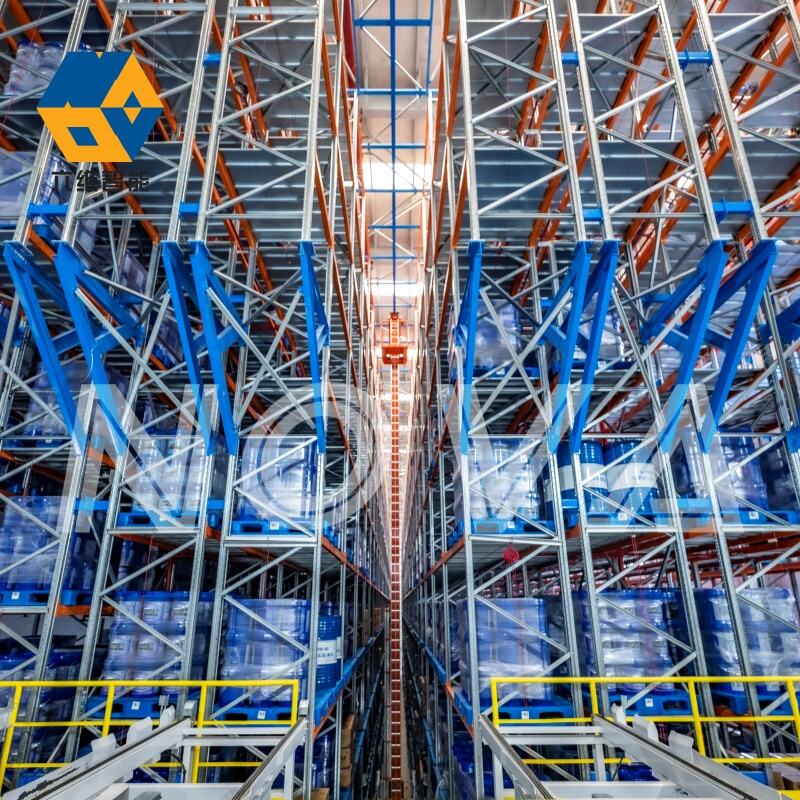

An automated storage and retrieval system maximizes warehouse space utilization through vertical storage configurations that extend far beyond traditional manual reach capabilities. These systems efficiently utilize ceiling heights that remain inaccessible to conventional forklift operations, often increasing storage density by 200-400% compared to traditional warehouse layouts. The precision positioning capabilities allow for minimal aisle widths while maintaining full accessibility to all storage locations.

Dynamic space allocation algorithms continuously analyze inventory turnover rates to position frequently accessed items in optimal locations within the automated storage and retrieval system. This intelligent positioning reduces average retrieval times while balancing system workloads across all available storage zones. The system automatically adjusts storage assignments based on seasonal patterns, promotional activities, and changing customer demand profiles.

Labor Cost Reduction

Implementation of an automated storage and retrieval system significantly reduces labor requirements by eliminating manual picking activities and minimizing human involvement in routine storage operations. Workers can focus on higher-value activities such as quality control, customer service, and strategic planning while robots handle repetitive storage and retrieval tasks. This workforce optimization typically results in 60-80% reduction in labor costs associated with traditional warehouse operations.

The reduction in physical labor demands creates safer working environments by removing workers from potentially hazardous situations involving heavy lifting, elevated platforms, and moving machinery. An automated storage and retrieval system operates consistently without fatigue, breaks, or shift changes, providing continuous operational capability that supports extended business hours and peak demand periods. The predictable operational patterns enable accurate labor planning and resource allocation across different business functions.

Technology Integration Benefits

Real-Time Inventory Management

Real-time inventory visibility represents one of the most significant advantages of implementing an automated storage and retrieval system, providing instant access to accurate stock levels and location data across all storage zones. This comprehensive tracking capability eliminates inventory discrepancies commonly associated with manual counting processes while providing detailed audit trails for compliance requirements. The system automatically updates inventory records as items move through storage and retrieval cycles.

Advanced tracking technologies within the automated storage and retrieval system utilize barcode scanning, RFID technology, and computer vision systems to verify item identity and condition throughout the storage process. These multiple verification points ensure inventory accuracy while detecting potential quality issues before items reach customers. The integration of serialized tracking capabilities enables lot-level traceability for industries requiring detailed product genealogy records.

Scalability and Flexibility

Modern automated storage and retrieval system designs incorporate modular architectures that support incremental expansion without disrupting existing operations. Companies can add additional storage modules, robotic units, or control zones as business requirements evolve, protecting initial investment while accommodating growth. This scalability ensures that warehouse automation investments remain viable throughout changing business cycles and market conditions.

The flexibility inherent in automated storage and retrieval system configurations allows adaptation to diverse product types, packaging formats, and handling requirements within single installations. Configurable storage compartments accommodate everything from small electronic components to large automotive parts while maintaining consistent operational parameters. Software-defined operational rules enable rapid reconfiguration to support seasonal products, promotional items, or new product introductions without physical infrastructure changes.

Performance Metrics and ROI

Throughput Capabilities

Throughput performance represents a critical measurement of automated storage and retrieval system effectiveness, with modern installations typically achieving 200-500 picks per hour per robotic unit depending on configuration and product characteristics. These performance levels far exceed manual picking capabilities while maintaining consistent accuracy rates above 99.9% across extended operational periods. The system's ability to operate continuously without performance degradation ensures predictable throughput during peak demand periods.

Advanced queuing algorithms within the automated storage and retrieval system optimize pick sequences to minimize travel distances while balancing workloads across multiple robotic units. This intelligent coordination prevents bottlenecks while ensuring that urgent orders receive priority processing without compromising overall system efficiency. Performance monitoring capabilities provide real-time visibility into throughput metrics and identify optimization opportunities for continuous improvement initiatives.

Return on Investment Analysis

Financial analysis of automated storage and retrieval system implementations typically demonstrates positive return on investment within 18-36 months through combined labor savings, space optimization, and inventory accuracy improvements. The elimination of picking errors reduces customer service costs while improving customer satisfaction and retention rates. Reduced insurance premiums often result from improved safety records and lower worker compensation claims associated with automated operations.

Long-term financial benefits of an automated storage and retrieval system include reduced facility expansion requirements due to increased storage density, lower utility costs through optimized space utilization, and improved inventory turnover rates that reduce carrying costs. The system's ability to operate in lights-out environments further reduces energy consumption while extending operational hours without additional labor costs. Predictable maintenance schedules and component lifecycles enable accurate budgeting for ongoing operational expenses.

Implementation Considerations

Site Preparation Requirements

Successful implementation of an automated storage and retrieval system requires careful site preparation including structural assessments to ensure adequate floor loading capacity and ceiling height clearances. Electrical infrastructure must support high-density charging stations and control systems while network connectivity provides sufficient bandwidth for real-time data transmission. Temperature and humidity control systems maintain optimal operating conditions for electronic components and stored products.

Integration planning for an automated storage and retrieval system involves coordinating with existing warehouse management systems, enterprise software platforms, and material handling equipment to ensure seamless operational transitions. Detailed workflow analysis identifies integration points where human operators interface with automated systems to maintain efficiency while preserving operational flexibility. Change management processes prepare staff for new operational procedures and technology interactions.

Training and Change Management

Comprehensive training programs ensure successful adoption of automated storage and retrieval system technologies by providing hands-on experience with control interfaces, maintenance procedures, and troubleshooting protocols. Cross-training initiatives develop multi-skilled operators capable of managing various system functions while maintaining operational continuity during staff transitions. Ongoing education programs keep operators current with software updates and system enhancements.

Change management strategies address organizational culture shifts associated with automated storage and retrieval system implementation by clearly communicating benefits, addressing concerns, and involving staff in optimization processes. Regular feedback sessions identify operational challenges and improvement opportunities while building confidence in automated systems. Performance incentives align individual goals with system optimization objectives to encourage continuous improvement initiatives.

FAQ

How long does it take to implement an automated storage and retrieval system

Implementation timelines for an automated storage and retrieval system typically range from 6-18 months depending on system complexity, facility size, and integration requirements. The process begins with detailed site analysis and system design, followed by manufacturing and component delivery phases. Installation and commissioning activities require 2-4 months for most standard configurations, with additional time needed for staff training and operational optimization.

What maintenance requirements are associated with automated systems

Maintenance requirements for an automated storage and retrieval system include daily visual inspections, weekly lubrication schedules, and monthly calibration procedures for robotic components. Preventive maintenance programs typically require 2-4 hours per week per robotic unit, with most tasks performed during normal operational periods. Annual comprehensive inspections ensure continued compliance with safety standards and optimize system performance parameters.

Can existing warehouses be retrofitted with automated systems

Most existing warehouses can accommodate automated storage and retrieval system installations with appropriate structural modifications and infrastructure upgrades. Retrofit projects require careful analysis of floor loading capacity, ceiling heights, and electrical systems to ensure compatibility with automated equipment. Modular system designs minimize disruption to ongoing operations while enabling phased implementation approaches that maintain business continuity.

What types of products work best with automated storage systems

An automated storage and retrieval system performs optimally with standardized products featuring consistent dimensions, weights, and packaging formats. Small to medium-sized items with regular shapes adapt well to automated handling systems, while fragile or irregularly shaped products may require specialized handling attachments. The system accommodates diverse product portfolios through configurable storage compartments and adjustable handling parameters that adapt to specific product characteristics.